Chapter 13: Wrap-Up

Chapter Overview

Chapter 13 will serve as an overview and wrap-up of all the important concepts discussed thus far. The skill, knowledge, techniques and methodology presented in this text are designed specifically to aid beginning electricians in forming a solid foundation for a long and productive career. Chapter information link.

- A solid foundation and understanding of electrical theory is indispensable knowledge when safely working with electrical equipment and systems of all types and sizes.

- Your ability to trouble shoot any system is directly related to your level of understanding associated with what you are working with and how familiar you are with a specific system.

- When working around or maintaining electrical equipment and associated systems it is important to keep in mind that all electrical equipment and associated systems have a limited operating life span based on usage or operating conditions and environmental factors.

Key points to remember:

Basic electrical theory underpins all electrical systems including their safe installation and operation. Being familiar with how and why systems operate safely and efficiently will help with not only the initial installation but also the safe operation and ongoing maintenance associated with electrical systems of all scales. Remember that your personal safety is ultimately your own responsibility, but being able to properly identify hazards and how to safely work around them can vastly improve your chances of a long and injury free electrical career.

Understanding basic electrical quantities, what they represent, and how to select the correct meter to safely measure a specific electrical quantity is important for anyone working around or with inherently dangerous electricity. Ohm’s law is a useful formula for not only determining unknown quantities in any electrical circuit, but arguably more importantly for understanding the relationships between voltage, current and resistance values and what they tell us about the state of the circuit you are examining.

Putting it all together

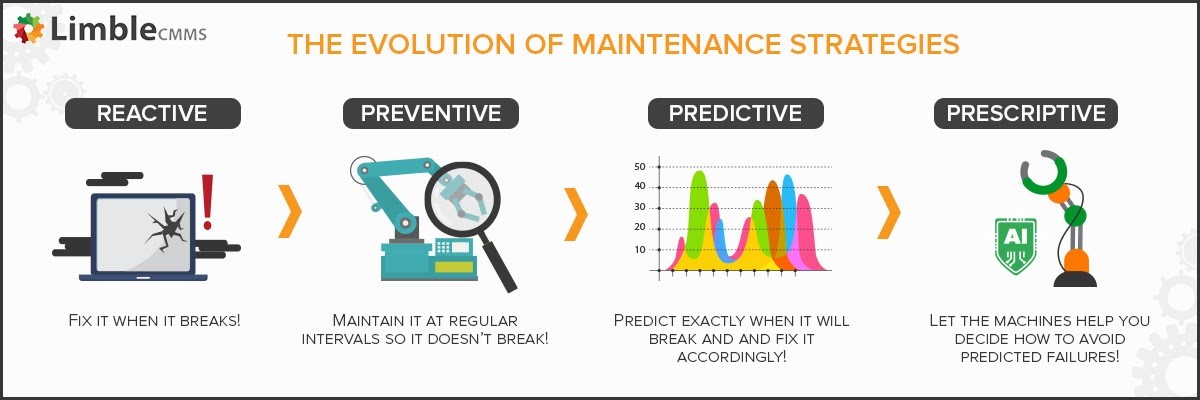

All electrical systems are designed to last for a limited rated life expectancy provided they are properly installed and periodically maintained. This would include inspection and recommended follow-up actions. With this in mind, maintenance can be divided into reactive, preventive, and predictive maintenance categories all centered around system reliability. Reactive maintenance is the least effective approach as it comes into play only after a potentially costly downtime event has occurred. Preventive maintenance is centered around physical inspection and individual usage interval. Predictive maintenance is more proactive and predicts the maintenance regimen based on the condition and service life of a specific system.

Image source: What is Predictive Maintenance? | Limble CMMS

Keep in mind

Remember it is always easier to maintain systems regularly as opposed to replacement after a potentially catastrophic failure. It is important to identify any existing or potential issues to prevent costly unscheduled shutdowns and associated downtime. Environmental factors including moisture, contaminants, and extreme/fluctuations in temperature can significantly reduce the expected operating life expectancy of electrical equipment. Physical Inspections should be performed periodically on electrical equipment for the visual evidence associated with installation errors, equipment subassembly failures, poor equipment condition, and/or overheating. In environments where there is an extreme exposure to adverse conditions, the frequency of inspections should be increased as conditions warrant.

Crucial problem-solving skill involving the systematic elimination of the various parts of a system to isolate a problem.

Ohm’s law states that current in a circuit is proportional to the voltage and inversely proportional to the resistance. Any unknown value can be determined when the other two values are known.